In the fast-evolving globe of electronics, the value of printed circuit boards (PCBs) can not be overstated. PCBs work as the backbone of modern-day electronic devices, helping with links in between numerous components and ensuring everything functions effortlessly. With a substantial array of terminologies surrounding circuit board manufacturing, comprehending the nuances can be rather frustrating. This post dives right into an extensive range of terms related to PCBs and their assembly, such as motherboard assembly, PCB design guidelines, flexible printed circuits, and high-density interconnects, to name a few.

A printed circuit card is an elaborate structure made by layering conductive pathways onto a shielding substrate. These paths are necessary for attaching different electronic components, such as resistors, capacitors, and microcontrollers, making PCBs essential for device functionality. When making PCBs, manufacturers have to think about elements like trace width and current, impedance control, and a selection of aspects that add to the general performance of the electronic motherboard. Parametric factors to consider such as the size of the PCB, the density of interconnections, and the products utilized can greatly affect both performance and manufacturability.

With advancements in technology, the change towards high-density interconnect (HDI) PCBs has actually acquired grip, enabling for smaller, extra powerful tools that can effectively take care of enhancing information loads. HDI boards include finer pads and traces, shorter web links, and greater link density, making them vital for applications in smartphones, tablet computers, and other small electronics. Conversely, flexible printed circuits (FPCs) have actually become a game-changer, offering bendable remedies that adapt numerous shapes and dimensions. This adaptability helps with the design of small and light-weight electronic devices that can quickly be incorporated right into products like wearables.

The manufacturing of flexible PCBs needs various strategies contrasted to standard rigid boards, including specialized products that can withstand duplicated bending without shedding connection. Making use of polyimide and other flexible substrates is crucial in making sure longevity and longevity. Furthermore, manufacturers frequently focus on inexpensive PCB boards to fit both high production volumes and budget plan restrictions, requiring effective manufacturing processes and supply chain practices.

When it concerns circuit card assembly (CCA), precision and accuracy are extremely important. With several components requiring placement on the board, the assembly process usually entails automatic machinery and strict quality assurance actions. Companies concentrating on PCB assembly, especially those providing quick turn services, have actually come to be rather popular, as they can deal with immediate prototyping demands while maintaining high standards of production top quality. Additionally, the development of smart and computerized PCB assembly technologies has actually substantially increased the rate and effectiveness of manufacturing processes, permitting decreased lead times and enhanced production capabilities.

In the realm of prototyping, the use of fast PCB prototyping services has actually become necessary for companies looking to bring their products to market swiftly. These services permit engineers to iterate swiftly, examining different setups and format designs, which is especially helpful when taking care of intricate RF circuits. Radio frequency design is an important area where exact PCB design plays an essential function, commonly incorporating numerous layers and complex routing to handle signal stability and lessen disturbance.

As understanding of PCB manufacturing expands, essential considerations need to likewise include the different elements of design, such as microvias and fiducials. Fiducial marks boost the precision of component positioning throughout assembly, while microvias permit more elaborate connections in HDI boards, enabling tighter spacing between traces. Buried and blind vias can even more enhance circuit density, providing chances for sophisticated circuit designs that push the boundaries of conventional PCB layouts.

In cases where power supply stability is crucial, heavy copper PCBs have gained acknowledgment as a durable service. These boards feature thicker copper layers to deal with high current loads, making them ideal for applications in power electronics, such as power supply boards and industrial circuits. The application of metal core products, such as aluminum or ceramic substratums, in particular PCB designs likewise aids in thermal administration, ensuring that heat is dissipated successfully, hence extending component life and improving reliability.

As the need for custom PCB boards proceeds to grow, manufacturers have adjusted their offerings to consist of a variety of customized options. Companies now offer considerable personalization alternatives, so developers can specify everything from the variety of layers in their board to particular component positionings, hence guaranteeing the final item meets their specific specs. These considerations often connect back to comprehensive PCB cost estimators, which aid clients understand exactly how different design selections will influence their general budget.

With international competition intensifying, lots of electronic component manufacturers are emphasizing quick turn PCB fabrication, allowing them to respond swiftly to market demands. This service permits engineers to settle designs and receive physical PCBs in an issue of days, which can make a significant distinction in R&D cycles. Furthermore, the growth of Chinese PCB assembly and manufacturing companies has actually resulted in a varied supply chain, providing extra alternatives for companies wanting to lower costs while preserving top quality.

Lightweight and compact designs are not just classy; they are indicative of a change amongst consumers towards even more mobile electronic solutions. Because of this, circuit card manufacturers are buying state-of-the-art technologies and materials to create slim, high-density interconnects that do not compromise on power or performance. The combination of HDI strategies such as consecutive lamination and laser drilling has allowed manufacturers to push the dimensions of pads and traces to formerly impossible limits, paving the method for advanced applications throughout numerous sectors.

As PCB technology continues to advancement, the interplay with complementary fields like IoT and synthetic intelligence has begun to shape the future of circuit card applications. With boosting connection needs, PCBs in wise gadgets need to use durable links while preserving ideal performance under varying environmental conditions. The development of new materials and manufacturing techniques is vital in meeting those obstacles, emphasizing the need for continuous technology within the PCB manufacturing domain name.

As eco-consciousness expands in customer choices, the market has placed a better focus on sustainable PCB manufacturing processes. From the option of recyclable products to the application of green production methods, manufacturers are progressively aware of their ecological impact. This pattern has brought about conversations concerning the value of accountable sourcing of basic materials, with an eye towards lessening electronic waste and improving power effectiveness across the lifecycle of PCBs.

The printed circuit board assembly (PCBA) plays an important role in the development and manufacturing of electronic tools. This process includes the intricate setup of electronic components on a PCB, guaranteeing precise positioning, soldering, and quality control to generate a trusted final product. High-density interconnect (HDI) PCBs are increasingly coming to be significant in the marketplace because of their capacity to pack even more traces into a smaller sized location, enabling greater performance without increasing the size of the tool. These boards commonly require specific manufacturing techniques like microvias and blind vias, adding to a durable design that satisfies the needs of high-frequency applications, such as those in the telecommunications market.

As modern technology breakthroughs, the design of circuit boards is advancing also. Flexible PCBs supply convenience in design and can be designed or curved to fit a range of applications, from wearables to automobile electronics.

The development of materials used in PCB manufacturing has actually opened up possibilities for greater performance and longevity. Ceramic PCBs are ending up being popular for their premium thermal performance and warmth dissipation abilities, making them ideal for applications that produce significant warm.

In the realm of PCB design, considerations such as impedance control play a crucial duty in ensuring signal integrity, especially in high-frequency applications. Advanced software application devices are significantly employed for PCB design, allowing engineers to forecast the efficiency and simulate of various designs before physical prototypes are made.

To conclude, the world of printed circuit card is varied and complicated, enveloping a vast selection of technologies and manufacturing techniques that maintain rate with our increasingly electronic way of lives. Recognizing terms like PCB assembly, design guidelines, quick prototyping, flexible circuits, and high-density interconnects is essential for those venturing right into the area of electronics. As modern technology breakthroughs, it is clear that these items of complex art and design will remain to play a critical role in the ceaseless drive towards innovation in electronic tools. From prototyping fiducials pcb to automation, the development of circuit board engineering guarantees to fuel advancements in plenty of applications, inevitably redefining what is feasible in our interconnected world.

Luke Perry Then & Now!

Luke Perry Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Freddie Prinze Jr. Then & Now!

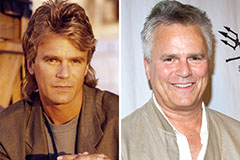

Freddie Prinze Jr. Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!